- WhatsApp: / 008613773256419

- Email: Jessy@fillex-packer.com

The machine is developed for mineral water , pop-top cans ,glass bottle ,beer etc .Combination packing ,with stable function ,and the packed articles tight and orderliness .This is a fully automatic production line integrarted with such processed as automatic conveying ,feeding ,tube management ,cutting ,shrinking ,and cooling shape-fixing flow .For large collectively counted case (box or can )packing ,it is preferred to encase with PE or PVC shrinking film before shrink packaging.

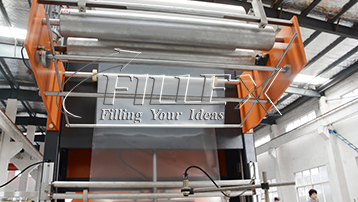

Professional Supplier of Packig Machine Automatic PE Film Wrapping Shrinking Machine

Auto beverage bottle shrink wrapping Machine can be used not only stand-alone, but also with other devices composed of packaging production line. It can be automatically arranged, collected row with PET beverage bottles or other similar items, and then shrink-wrapped. Finally, by shrinking, cooling and sizing out the finished product. Packaged products are bundled firm, neat appearance, artistic, and easy to open. It is widely used in food, pharmaceutical, chemical, and other light industrial products and other industries.

Model | WSP-10(L-Type) | WSP-15(L-Type) | WSP-20(L-Type) | WSP-30(L-Type) |

Machine dimension(mm) | 6500*3200*2100 | 8500*3200*2100 | 13200*1100*2100 | 13840*1100*2100 |

Shrink tunnel dimension(mm) | 1800*650*450 | 1800*650*450 | 1800*650*450 | 2500*700*450 |

Max.package dimension(mm) | 600*400*350 | 600*400*350 | 600*400*350 | 600*400*350 |

Packing speed (bundles/min) | 8-10 (pcs/min) | 14-15 (pcs/min) | 16-20 (pcs/min) | 20-30 (pcs/min) |

Work voltage/power | 380V 19kw | 380V 19kw | 380V 30kw | 380V 30kw |

Working pressure | 0.6-0.8Mpa | 0.6-0.8Mpa | 0.6-0.8Mpa | 0.6-0.8Mpa |

Total weight | 1600kg | 2000kg | 2500kg | 2800kg |

Suitable to PE PVC film packaging.

PLC control system,automatic working.

Colorful touch-screen control panel,easy operate.

Bottle entering,auto unscarmbling bottle,pushing bottle,heat sealing-saw cutting,pressing PE,shrink,Cooling automatically.

The height of the conveyor shall be made towards client's demand,can handle 2*3/3*4/4*5/4*6 bottle per package.

Double air blowers,guarantees the temperature balance, in the shrink stove with PAD temperature controller that apparently saves energy.

The height of the conveyors shall be made towards client's demand.

Low Speed Shrink-Wrapping Packing Machine

● Designed for automatic packaging production lines such as beer, beverage, purified water, fruit juice, dairy and other beverages.

● With the transport feed, Li bottle, film, sealing, shrink, cooling stereotypes and other processes of the full automation function.

● using the world's most advanced film thermostat heat sealing technology, sealing clear and solid.

● PLC program with automatic cycle control, stable and reliable performance.

● original import guide rod cylinder, to ensure accurate action, durable.

● Unique shrinkage channel, two sets of centrifugal hot air circulation system, the heat balance evenly, shrink tightening, beautiful.

● This machine is protected by national patent technology.

Medium Speed Shrink-Wrapping Packing Machine

● suitable for beer, beverages, fruit juice, bottled water, dairy products, condiments and other bottom care or no base care cluster packaging.

● Unique film release device and film constant tension transmission, instantaneous film cut off, automatic lap wrap method, shrink the higher strength after packaging.

● servo motor control system, the lever into the bottle, film, film, film precision synchronization, stable and reliable.

Q1: Are you a trading company or a manufacturer?

A1: We have our own factory for many years,can give u best service.

Q2: What's your guarantee if we buy your machines?

A2: We offer you high quality machines with 1 year guarantee and free spare parts for 1 year. Meanwhile our engineers have rich experience and have gone to more than 50 countries for installation and commissioning.

Q3: When can I get my machine after I paid?

A3: We will deliver the machines on time as the date we agreed both side.

Q4: How can I install my machine when it arrives?

A4: Our engineer will go to your side as soon as you get your machines ready for testing and teaching your technicians how to run the machines.

Q5: What's the delivery time?

A5: 30-45 days after the T/T deposit or L/C.

Q6: Do you provide customized service?

A6: We can design the machines according to your requirements (material, power, filling type, container and etc), at the same time we will give you professional suggestion by many years industrial experience.