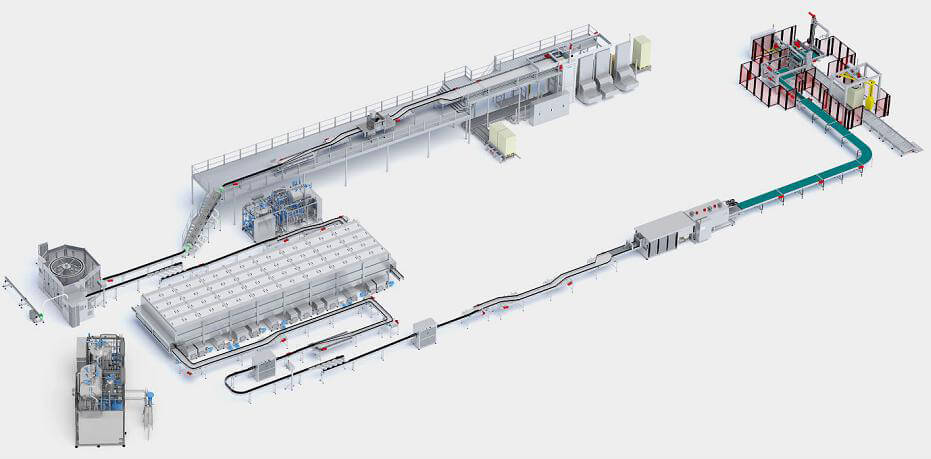

Water Treatment System

Different equipment used to produce pure water and mineral water.According to the membrane pore size,water treatment system include RO purifier,Nano purifier,UF purifier.After passing through the purifier,remove the bacteria and impurities from the water to make water quality can meet the drinking water standard.Treatment capacity up to 100,000L/H.

Beverage Processing System

The beverage blending system is a pre-treatment complete set of different juice drinks and carbonated drink beverages.All kind of raw materials,auxiliary material and water are extracted or dissolved according to the predetermined process parameters through varies process unit,then mixed adjust the obtain semi -finished products.Mainly includes hot water unit,dissolved sugar filter ...

Can De-palletizer

The automatic depalletizer is mainly suitable for the automatic depalletizing of the whole stack of empty cans. It lifts the empty cans stacked on the pallet from bottom to top and pushes them to the conveying chain. The can spraying can washing machine is used as a supporting tool to replace manual cans discharging and traditional empty can unloading machines, which can save a lot of labor and improve production capacity.

Can CSD Filling Machine

Our machine is suitable for cans beverage (beer) industry in the steam cans filling and sealing. Filling and sealing for the overall design, the use of isobaric filling principle.When filling, the empty can into the up cans pneumatic can holder, the compressed air through the pneumatic triple into the up can cylinder, and at the same time,the empty can and filling the valve under the taper to be ...

Packing System

Post packaging machine include PE film shrink wrapping machine,carton packing machine,it is used for secondary packaging of varies type of bottles.The packaging machines have the advantage of high automation,reliable control,simple adjustment,convenient operation and maintenance.Widely used in water,juice,carbonated drink,oil,wine,chemical,medical and other industrial ...

Conveyor System

Conveyor system include bottle warmer ,bottle cooler,pasteurization spray tunnel,chain conveyor,case conveyor.According to the products and different requirements to choose conveying equipment.Capacity up to 48,000bph

Palletizing System

The Automatic Palletizer can put different products in a fixed order and stack them on the pallet automatically. Number of product and layers can be set .easy for the fork moves the full pallet into storehouse. This equipment adopts PLC ,touch screen and intelligent managing which is not only simple and easy to master, but also reducing the labor.