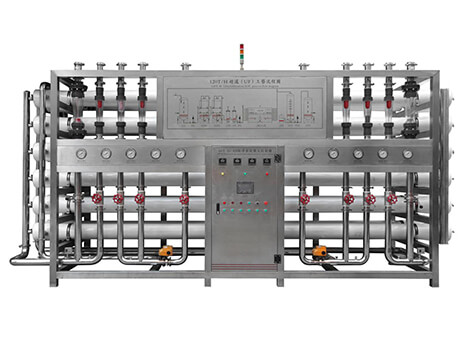

Water Treatment System

Different equipment used to produce pure water and mineral water.According to the membrane pore size,water treatment system include RO purifier,Nano purifier,UF purifier.After passing through the purifier,remove the bacteria and impurities from the water to make water quality can meet the drinking water standard.Treatment capacity up to 100,000L/H.

CSD Drink Processing System

The beverage blending system is a pre-treatment complete set of different juice drinks and carbonated drink beverages.All kind of raw materials,auxiliary material and water are extracted or dissolved according to the predetermined process parameters through varies process unit,then mixed adjust the obtain semi -finished products.Mainly includes hot water unit,dissolved sugar filter ...

Carbonated Drink Filling Machine

Adopt PLC as center control,make sure of pressure transmitter and electromagnetism pneumatic valve to measure liquid level For high output,liquid tank adopts an annular liquid tank to balance the pressure in the tank Adopt advanced magnet clutches for capping with adjustable torsional moment to insure capping safely and reliably.

Labeling System

According to the characteristics of the standard set, the mechanical structure, circuit design and intelligent control are improved to improve the production efficiency, meet the requirements of large manufacturers, and reduce the production cost for customers. Increased production efficiency. Due to the design of equal speed ratio, this machine completely realizes the purpose of standard setting, smooth table feeding, stable operation and fast mark cutting.

Packing System

Suitable for beer, beverage, fruit juice, bottled water, dairy products, condiments and other shrink film packaging.Unique film unwinding device and film constant tension transmission, film instantaneous cut off, automatic lap wrap method, shrink the higher strength after packaging.Servo motor control system, the lever into the bottle, film, film, film precision synchronization, stable and reliable...

Conveyor System

Conveyor system include bottle unsrambler ,tilting sterilizer,bottle warmer ,bottle cooler,pasteurization spray tunnel,chain conveyor,case conveyor.According to the products and different requirements to choose conveying equipment.Capacity up to 48,000bph

Palletizing System

The Automatic Palletizer can put different products in a fixed order and stack them on the pallet automatically. Number of product and layers can be set .easy for the fork moves the full pallet into storehouse. This equipment adopts PLC ,touch screen and intelligent managing which is not only simple and easy to master, but also reducing the labor.