- WhatsApp: / 008613773256419

- Email: Jessy@fillex-packer.com

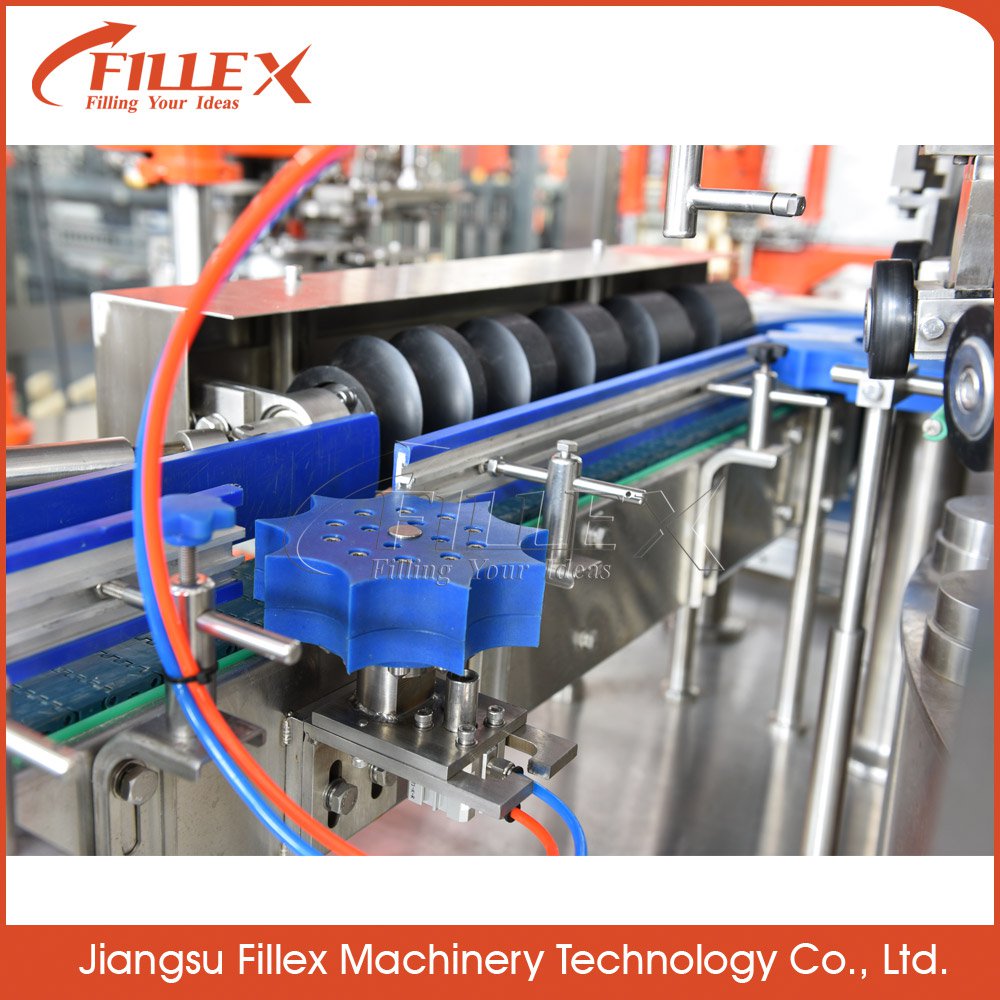

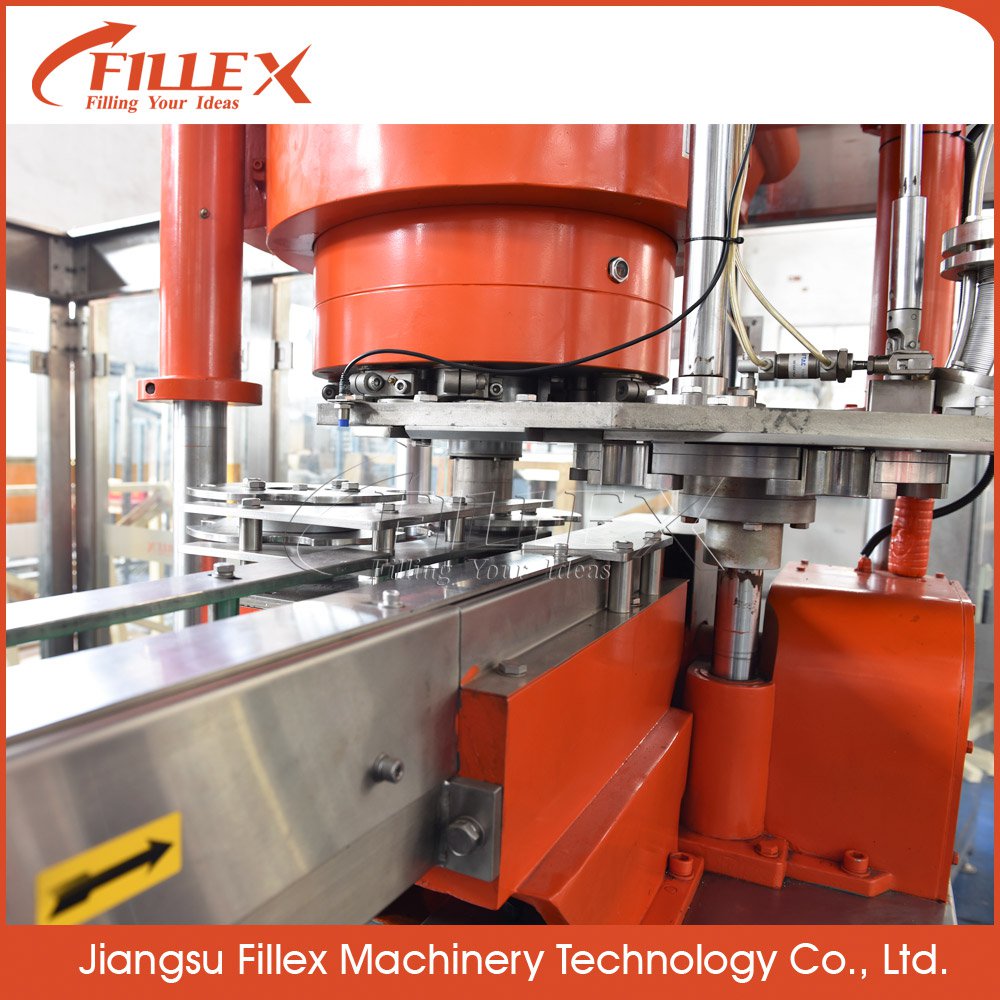

Our machine is suitable for cans beverage (beer) industry in the steam cans filling and sealing.Filling and sealing for the overall design, the use of isobaric filling principle, When filling, the empty can into the up cans pneumatic can holder, the compressed air through the pneumatic triple into the up can cylinder, and at the same time,the empty can and filling the valve under the taper to be sealed, Filling valve translocation fast block in the role of another cylinder to open the valve,Inflate empty cans

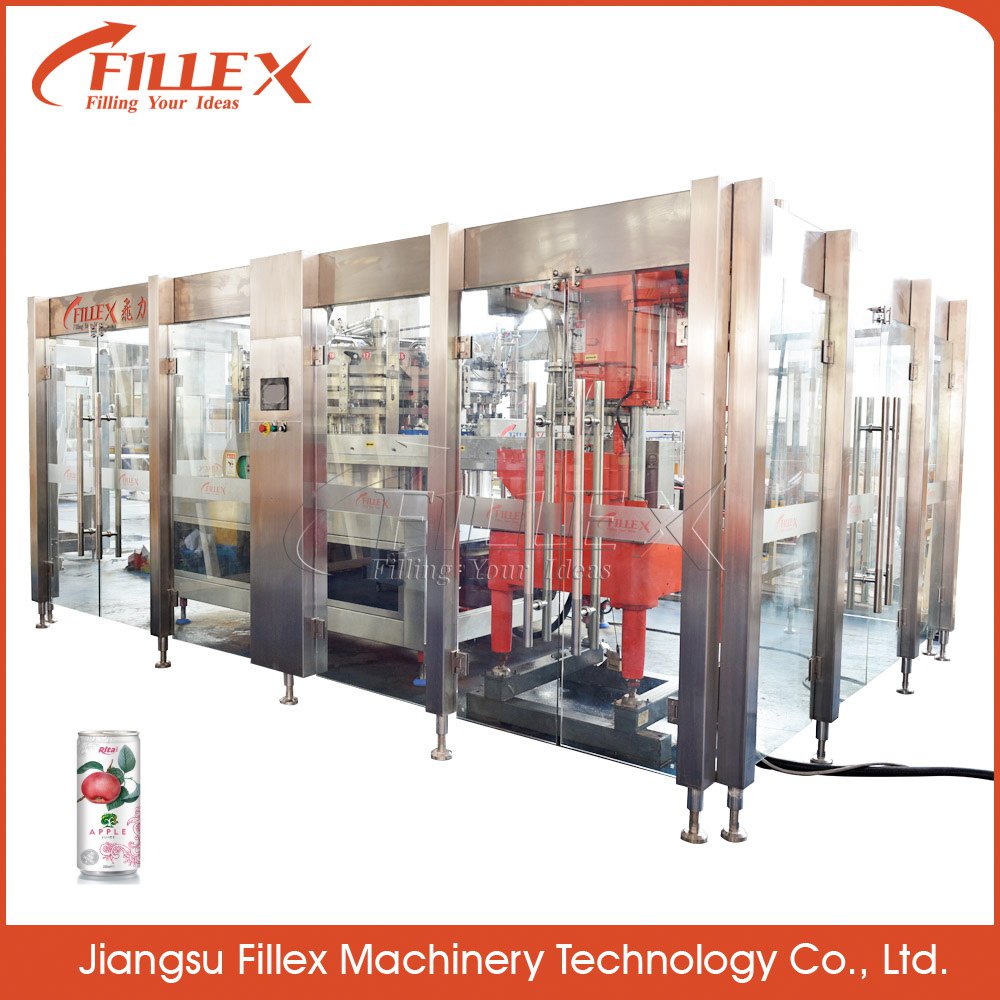

Automatic Beverage Can Filling packing line

Application:

Product Description of can beverage filling machine

Application: water, juice, tea, energy drinks, etc.

Suitable for: Aluminum can, pop can and PET can

Filling system: Gravity or isobaric filling

Production capacity: 1, 000CPH - 36, 000CPH (250ml)

| Model(CFS-C) | 12-4 | 18-4 | 24-4 | 32-4 | 32-6 | 40-8 | 50-8 |

| Production Capacity | 4000CPH | 6000CPH | 9000CPH | 12000CPH | 15000 | 18000 | 22000 |

| Can Available | 52.5-99mm H 39-160mm | ||||||

| Power(kw) | 5.5 | 5.5 | 7.5 | 7.5 | 9.5 | 11.5 | 13.5 |

| Dimension(L*W*H)mm | 2700*1400*1900 | 2750*1750*1900 | 2750*2150*1900 | 3150*2150*1900 | 4150*2150*1900 | 4850*2150*1900 | 5550*2150*1900 |

Machine Pictures:

Can Filling Machinery are designed to fill carbonated soft drink( CSD ), juice into plastic cans or metal cans

for the CSD filling, adpoted the negative filing nozzle

for the Juice filling, adppted the refluence hot filling

As the machine head structure is simplified, the adjustment and maintenance become more convenient. Generally, the employees who have undergone short-term training can operate it skillfully.

Especially the improvedcurve sealing cam makes the sealing quality apparently better than other same products. The production adopts frequency conversion speed adjustment with touch screen operation. In addition, it is provided with such features as no cap feeding in case of no can, and alarm of cap shortage. The appearance design of full stainless steel materials fully complies with food and sanitation requirements. Furthermore, the steam jetting device and remote control system can be equipped according to customer requirements. It is currently one of the most advance seaming devices in the country.

Q1: Are you a trading company or a manufacturer?

A1: We have our own factory for many years,can give u best service.

Q2: What's your guarantee if we buy your machines?

A2: We offer you high quality machines with 1 year guarantee and free spare parts for 1 year. Meanwhile our engineers have rich experience and have gone to more than 50 countries for installation and commissioning.

Q3: When can I get my machine after I paid?

A3: We will deliver the machines on time as the date we agreed both side.

Q4: How can I install my machine when it arrives?

A4: Our engineer will go to your side as soon as you get your machines ready for testing and teaching your technicians how to run the machines.

Q5: What's the delivery time?

A5: 30-45 days after the T/T deposit or L/C.

Q6: Do you provide customized service?

A6: We can design the machines according to your requirements (material, power, filling type, container and etc), at the same time we will give you professional suggestion by many years industrial experience.