- WhatsApp: / 008613773256419

- Email: Jessy@fillex-packer.com

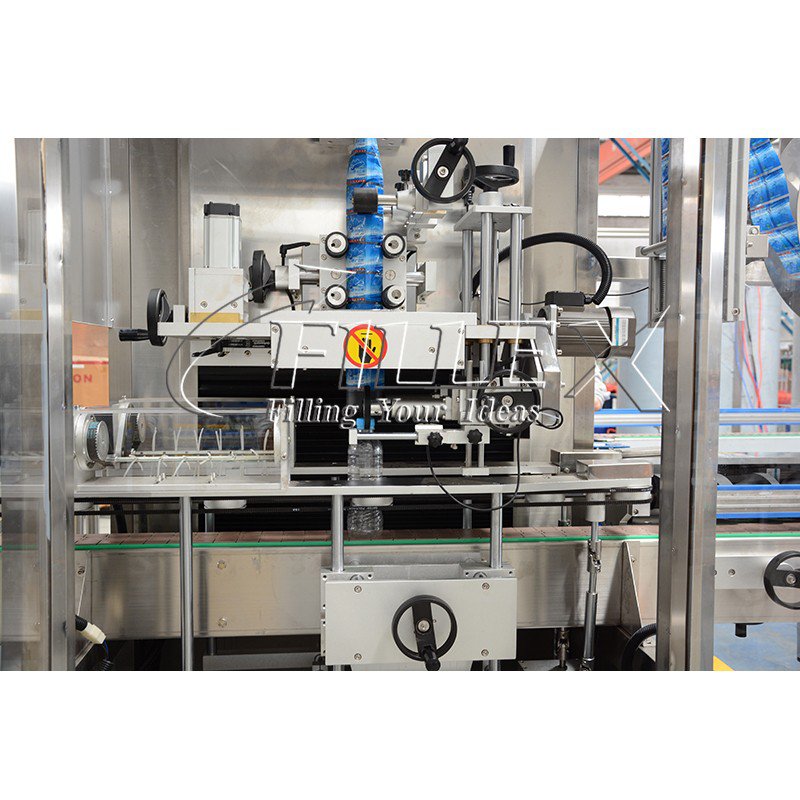

This auto shrink sleeve labeling machine is workable to apply PVC labels onto the water bottles or cans. It is widely used in the beverage and food industries.

The machine adopts international advanced technology; cover the circle label on the pet bottle.

And then hot shrinking to fix on the position which bottle body designated.

This machine's structure is compact, and suitable for the production line of different direction and different height.

The machinery part adopts combination designing of modularization, and makes the machine reasonable. The height adjustment adopts motor fluctuating; It is convenient to replace the material. The special cutter head designing, make the film-rolling cut more exactly and reliably.

| Model | SL-50 | SL-100 | SL-150 | SL-250 | SL-350 | SL-400 |

| Capacity | 3,000 | 6,000 | 9,000 | 15,000 | 21,000 | 24,000 |

| Container Diameter | 28mm-120mm | |||||

| Length of Label | 30mm-250mm | |||||

| Label Thickness | 0.03mm-0.13mm | |||||

| Dimension(mm) | 600*750*1800 | 2440*950*2100 | 2440*950*2100 | 2440*1000*2200 | 2440*1000*2200 | 2440*1000*2200 |

| Weight(kg) | 100 | 450 | 550 | 600 | 700 | 750 |

Synchronized transmission and drive by gear with one belt.

The new style cutting knife droved by servo motor, with high speed, more stable and precise .

Synchronous locating device enables the tolerable error to1mm .

Single material shelf with reasonable height in order to make it convenient to install label.

Wide range of applications for round bottle, square bottle, flat bottle etc.

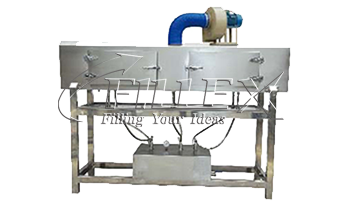

The whole machine 304 stainless steel shell, split design .

Water does not rust, structural stability, easy installation shift .

Seamless steel design, low pressure steam jet steam points the way.

Compact, lightweight H-type design, won a number of national patents.

High thermal efficiency, rapid warming, thus saving energy and operating costs.

A high degree of automation, fuzzy control module, a great convenience for users.

Modular design, demolition convenient, user-friendly maintenance

◆ Full Face Stainless Steel hosts: the whole machine is not waterproof rust;

◆ Adjustable cutter head: original cyclotron cut, double-sided blade, long life;

◆ Single positioning center guide pillar: Tag channeled more stable;

◆ synchronized dividing device: bottle feeding is more stable;

◆ Label brush under Group: sets of standard precision is more accurate;

◆ label control electric eye shelf: unique combination of tail and electric eye, improve membrane material cutting accuracy;

Q1: Are you a trading company or a manufacturer?

A1: We have our own factory for many years,can give u best service.

Q2: What's your guarantee if we buy your machines?

A2: We offer you high quality machines with 1 year guarantee and free spare parts for 1 year. Meanwhile our engineers have rich experience and have gone to more than 50 countries for installation and commissioning.

Q3: When can I get my machine after I paid?

A3: We will deliver the machines on time as the date we agreed both side.

Q4: How can I install my machine when it arrives?

A4: Our engineer will go to your side as soon as you get your machines ready for testing and teaching your technicians how to run the machines.

Q5: What's the delivery time?

A5: 30-45 days after the T/T deposit or L/C.

Q6: Do you provide customized service?

A6: We can design the machines according to your requirements (material, power, filling type, container and etc), at the same time we will give you professional suggestion by many years industrial experience.