- WhatsApp: / 008613773256419

- Email: Jessy@fillex-packer.com

With 15 years rich experience, Fillex beer production line with good quality, advanced technology, reasonable design, can produce high quality products to occupy the market, save cost, reduce the energy consumption and improve economic benefits.The main composition of the line is: unloading bottle machine, bottle washing machine, inspection machine, filling capping machine, sterilization machine, labeling machine, packing machine or heat shrinkable film packaging machine, etc.

Fillex Supply The Turnkey Service For Beer Production Line

Brewery System

According to the beer brewing process and technical requirements, brewery system is generally divided into: 1, raw material handling system 2, brewhouse 3. Fermentation sake system 4. Filtration system 5, CIP system 6, control system, and other auxiliary systems.

Beer Filling Machine

This machine is mainly used for the filling of beer and easy foaming products. Spring-style rinsing pliers,two internal and external washing,high washing efficiency;Pressure filling liquid level positioning,quantitative accuracy;Cantilever-type hygienic bottle tank are used to overcome secondary pollution caused by broken bottles;Double de-oxygen system.

Beer Pasteurization

Pasteurization is a disinfection method that uses a lower temperature to kill germs and maintain the flavor of nutrients in items. Beer will become sour after brewing, but the culprit that makes beer sour is Lactobacillus, so heating the beer at a temperature of 50~60°C for half an hour can kill Lactobacillus and spores in the beer without boiling. So it will not destroy the beer.

Labeling System

The whole machine can be used for bottles of different specifications, with simple adjustment and can be finished in a short time.This series of adhesive labeling machine is suitable for round bottle labeling in food, beverage, medicine, chemical industry, daily chemical industry, etc.The whole machine is designed and manufactured according to GMP requirements.

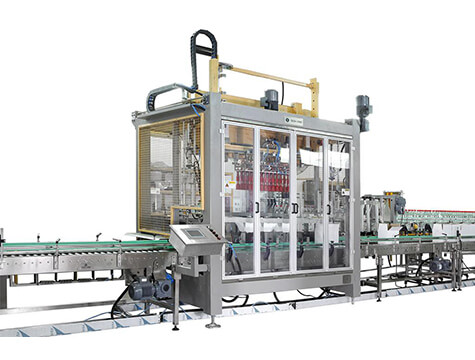

Packing System

It is suitable for carton packing of beer, beverage, bottled water, medicine, food, etc. The wrapping method of cardboard saves about 1/5 of the cost of packaging materials compared with the traditional packaging method.Use of well-known hot melt adhesive equipment, easy to operate, durable.Reasonable linear bottle feeding and board loading mechanical structure, reliable pneumatic device and advanced electronic control technology.

Conveyor System

Conveyor system include bottle warmer ,bottle cooler,pasteurization spray tunnel,chain conveyor,case conveyor.According to the products and different requirements to choose conveying equipment.Capacity up to 48,000bph

Palletizing System

The Automatic Palletizer can put different products in a fixed order and stack them on the pallet automatically. Number of product and layers can be set .easy for the fork moves the full pallet into storehouse. This equipment adopts PLC ,touch screen and intelligent managing which is not only simple and easy to master, but also reducing the labor.

About Us

Established in 2006, Fillex is a China based manufacturer of completely beverage production lines and possessed with 10,000 square meters standard workshop and more than 60 professional workers. Fillex has adhered to our long-term concept of “Packing Ideas”. We devote everyday to provide our customers excellent collaborative buying experience. If you are looking for a merchandise of machines of Beer Production Line, please don't hesitate to contact us!