- WhatsApp: / 008613773256419

- Email: Jessy@fillex-packer.com

Ultrafiltration (UF) is a type of membrane filtration in which hydrostatic pressure forces a liquid against a semipermeable membrane. A semipermeable membrane is a thin layer of material capable of separating substances when a driving force is applied across the membrane. Once considered a viable technology only for desalination, membrane processes are increasingly employed for removal of bacteria and other microorganisms, particulate material, and natural organic material, which can impart color, tastes, and odors to the water and react with disinfectants to form disinfection byproducts (DBP). As advancements are made in membrane production and module design, capital and operating costs continue to decline.

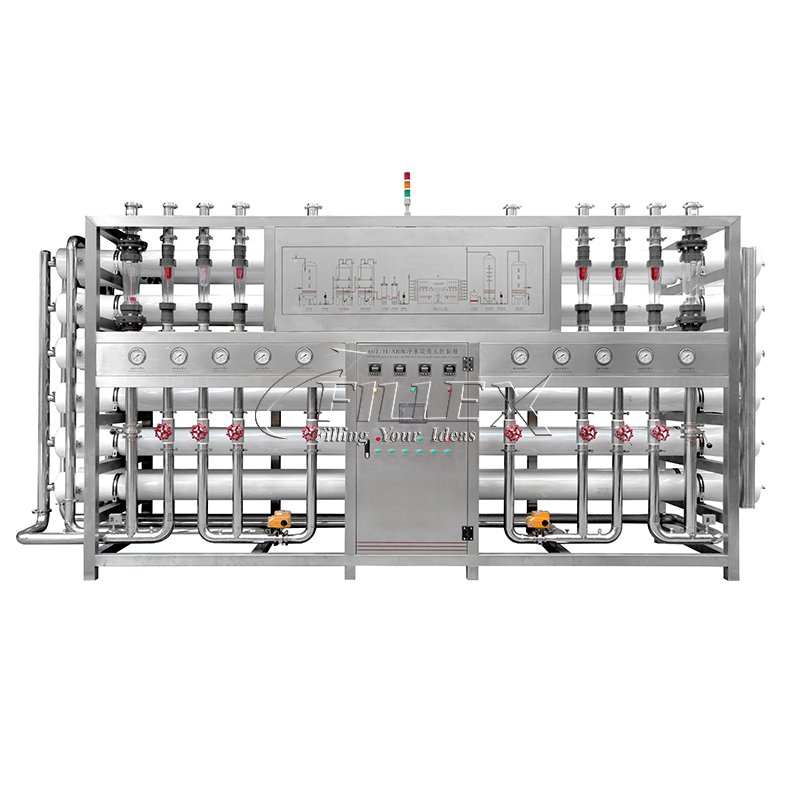

UF Hollow Fiber Membrane Mineral Water Treatment System

UF membrane is only allows the solvent(such as water molecules), mineral salts and small molecular organic substances in the solution to pass through, and the macromolecular substances such as suspended matter, colloid, protein and microorganisms in the solution are intercepted, Thereby achieving the purpose of purification or separation.

| Model | Processing water volume(m³/h) | Power(KW) | Inlet pipe | Outlet pipe | Dimensions(L*W*H mm) |

| UF-1 | 1 | 1.1 | DN32 | DN25 | 2000*700*1700 |

| UF-2 | 2 | 1.3 | DN32 | DN32 | 2500*1000*1700 |

| UF-3 | 3 | 1.5 | DN32 | DN32 | 3000*1000*1700 |

| UF-5 | 5 | 1.75 | DN50 | DN40 | 3300*1000*1700 |

| UF-8 | 8 | 2.1 | DN50 | DN50 | 2500*1000*1800 |

| UF-10 | 10 | 2.4 | DN50 | DN50 | 2800*1000*2000 |

| UF-15 | 15 | 4.8 | DN65 | DN65 | 2800*1200*2000 |

What's the working principle of Ultrafiltration membrane?

Ultrafiltration membrane is the anisomerous semipermeable membrane made of macro molecule material as the separation method without phase transition for solution, and can remove particles whose molecule weight ranges 1,500-100,000 Dalton,and can effectively remove organic,bacterium,virus,colloid and non-ion suspended solid.

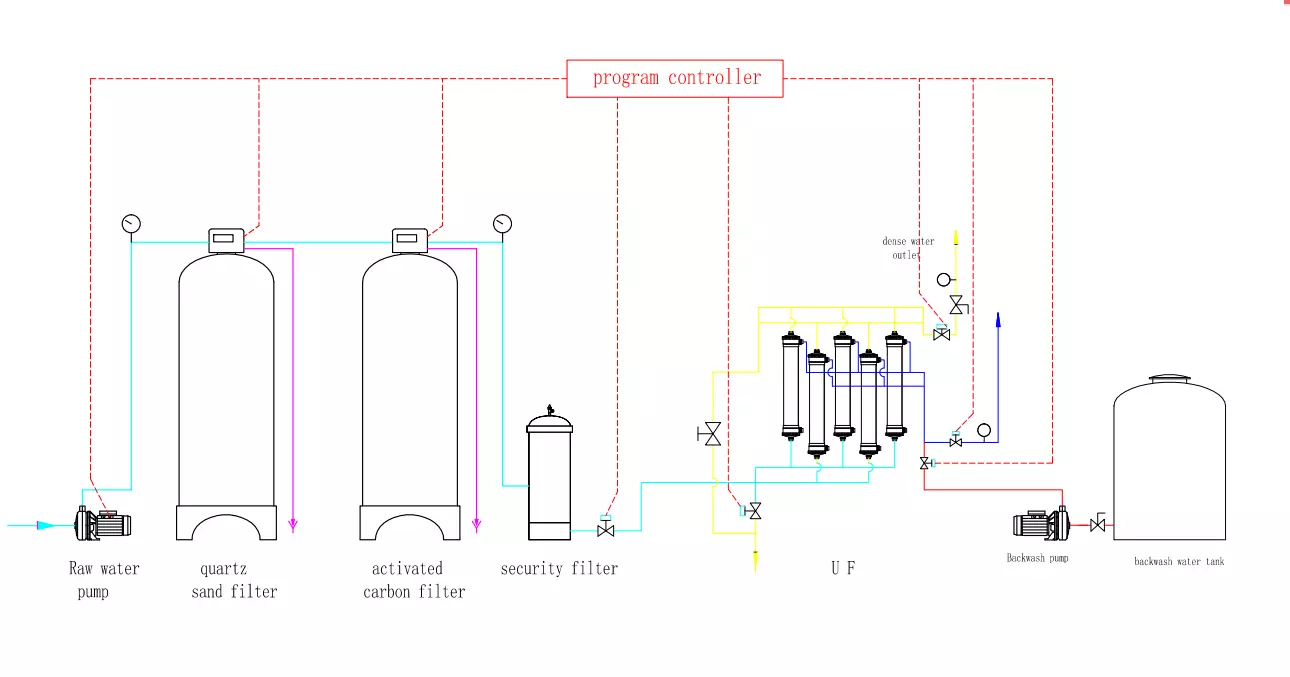

STEP<1>. Sand Filter: to use sand media down to 0.5-1mm. which filter size can be down to 200micron. some big suspended solids like coolloids, rust, mud, imparity etc can be trapped by media bed. and be removed from water.

STEP<2>. Carbon Filter: can absorb some organism, dissolved air, odor & color matter etc.

STEP<3>. Softener: use cation exchange resin to remove Calcium, Magnesium etc to make soft water.

STEP<4>. Micron Filter: use 5 -20 micron sediment cartridge filter / bag filter, to remove the passed suspended solid from pre-treatment. so that more safty for entrance of RO.

STEP<5> Ultra-filtration system (UF membrane to trapped most of ions. to de-mineralize/desaltination etc. it will be PURE WATER from output.

Q1: Are you a trading company or a manufacturer?

A1: We have our own factory for many years, can give u best service.

Q2: What's your guarantee if we buy your machines?

A2: We offer you high-quality machines with a 1-year guarantee and free spare parts for 1 year. Meanwhile, our engineers have rich experience and have gone to more than 50 countries for installation and commissioning.

Q3: When can I get my machine after I paid?

A3: We will deliver the machines on time as the date we agreed on both sides.

Q4: How can I install my machine when it arrives?

A4: Our engineer will go to your side as soon as you get your machines ready for testing and teaching your technicians how to run the machines.

Q5: What's the delivery time?

A5: 30-45 days after the T/T deposit or L/C.

Q6: Do you provide customized service?

A6: We can design the machines according to your requirements (material, power, filling type, container and etc), at the same time we will give you professional suggestion by many years industrial experience.