- WhatsApp: / 008613773256419

- Email: Jessy@fillex-packer.com

Fully Automatic 3 / 5 Gallon Bottle / Barrel Water Filling Machine / Production Line

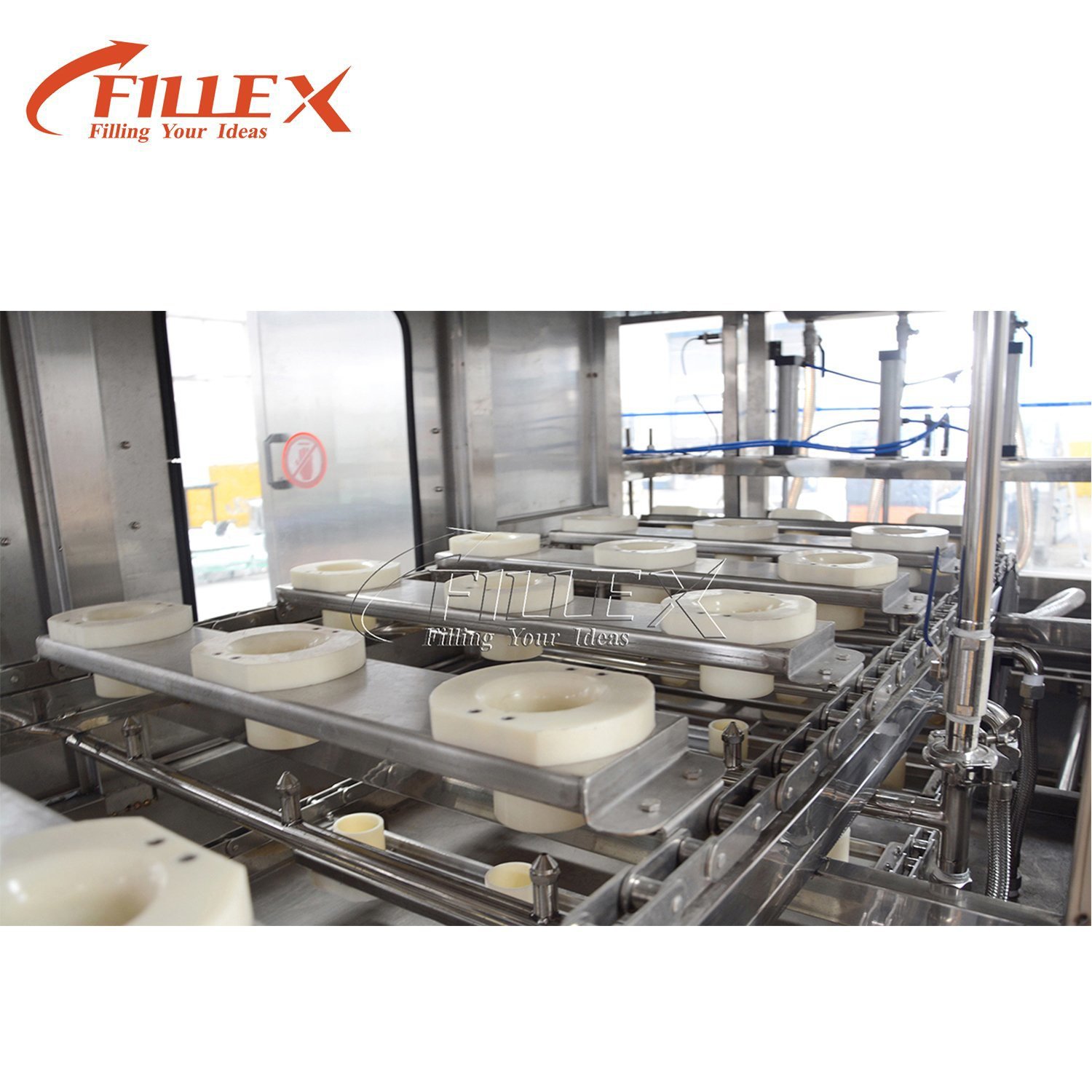

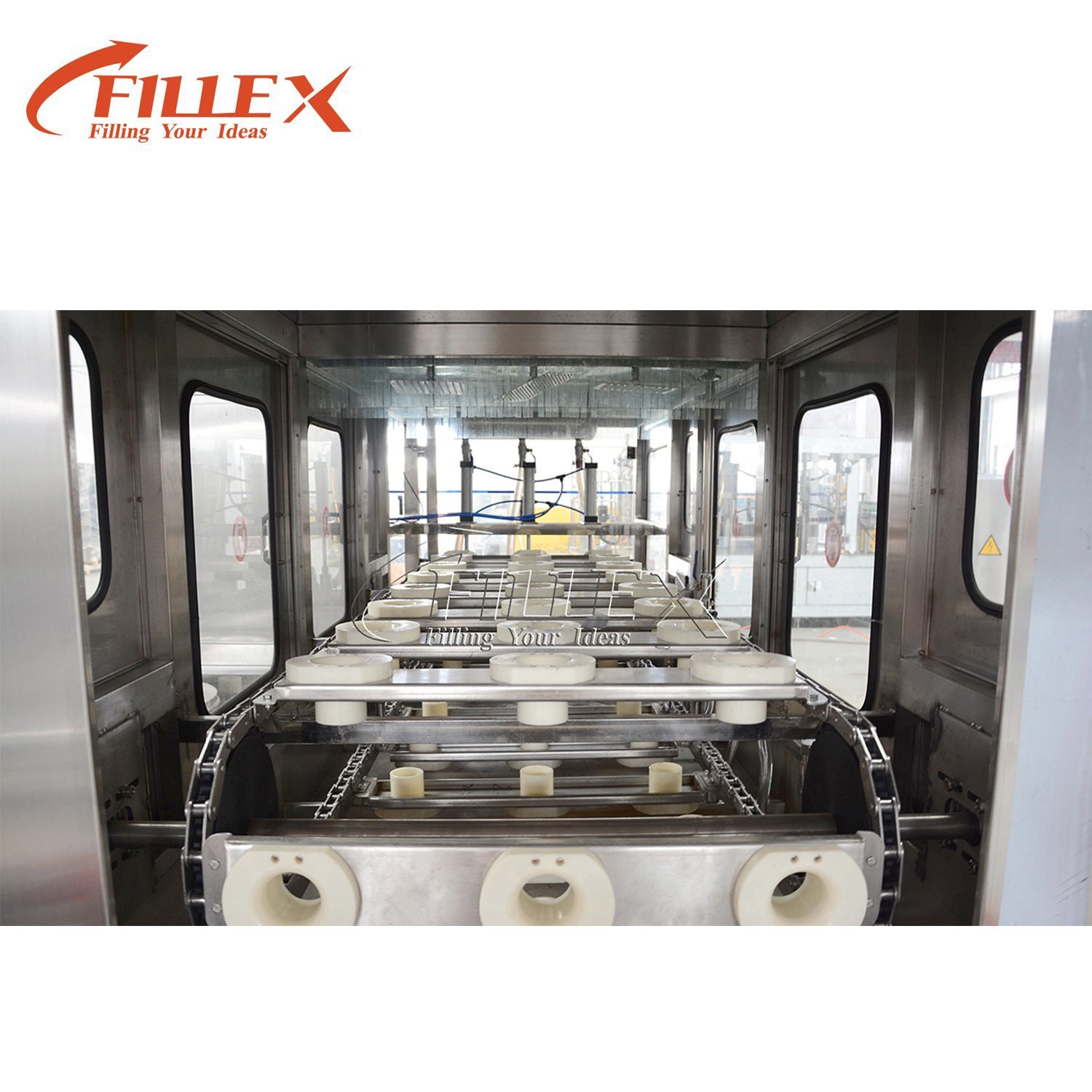

3/5 Gallon water filling machine is mainly applied for the filling of beverage. This machine contains 3 parts: Rinser, Filler and Capper. It works harmoniously with air-conveyor belt, It holds the bottles by the neck, thus, reducing the possibility of bottles falling over during conveying process. This drinking water filling equipment adopts bottle neck holding transmission technology to realize fully automatic rinsing, filling and capping.

| Model | QGF-80 | QGF-150 | QGF-300 | QGF-450 | QGF-600 | QGF-900 |

| Filling heads | 1 | 1 | 2 | 3 | 4 | 6 |

| Filling volume | 18.9 | 18.9 | 18.9 | 18.9 | 18.9 | 18.9 |

| Barrel size | φ270×490 | φ270×490 | φ270×490 | φ270×490 | φ270×490 | φ270×490 |

Production capacity (BPH) | 80 | 150 | 300 | 450 | 600 | 900 |

| Gas pressure(KPA) | 0.4-0.6 | 0.4-0.6 | 0.4-0.6 | 0.4-0.6 | 1 | 1.2 |

| Gas consumption | 0.37 | 0.37 | 0.6 | 0.8 | 1 | 1.2 |

| Motor power(KW) | 1.38 | 1.75 | 3.8 | 3.8 | 7.5 | 9 |

| Motor voltage | 380V/50HZ | 380V/50HZ | 380V/50HZ | 380V/50HZ | 380V/50HZ | 380V/50HZ |

| Weight(KG) | 500 | 700 | 1200 | 1600 | 2000 | 3500 |

Overall dimension(MM) | 2500×1100×1600 | 2800×1100×1600 | 3800×1300×1600 | 4200×1600×1600 | 4800×800×1600 | 4200×2300×1600 |

3 / 5 Gallon Bottle Filling Machine

1. About auto loading device

Energy saving

The material of machine frame and body: all 304 Stainless Steel

No bottles no washing

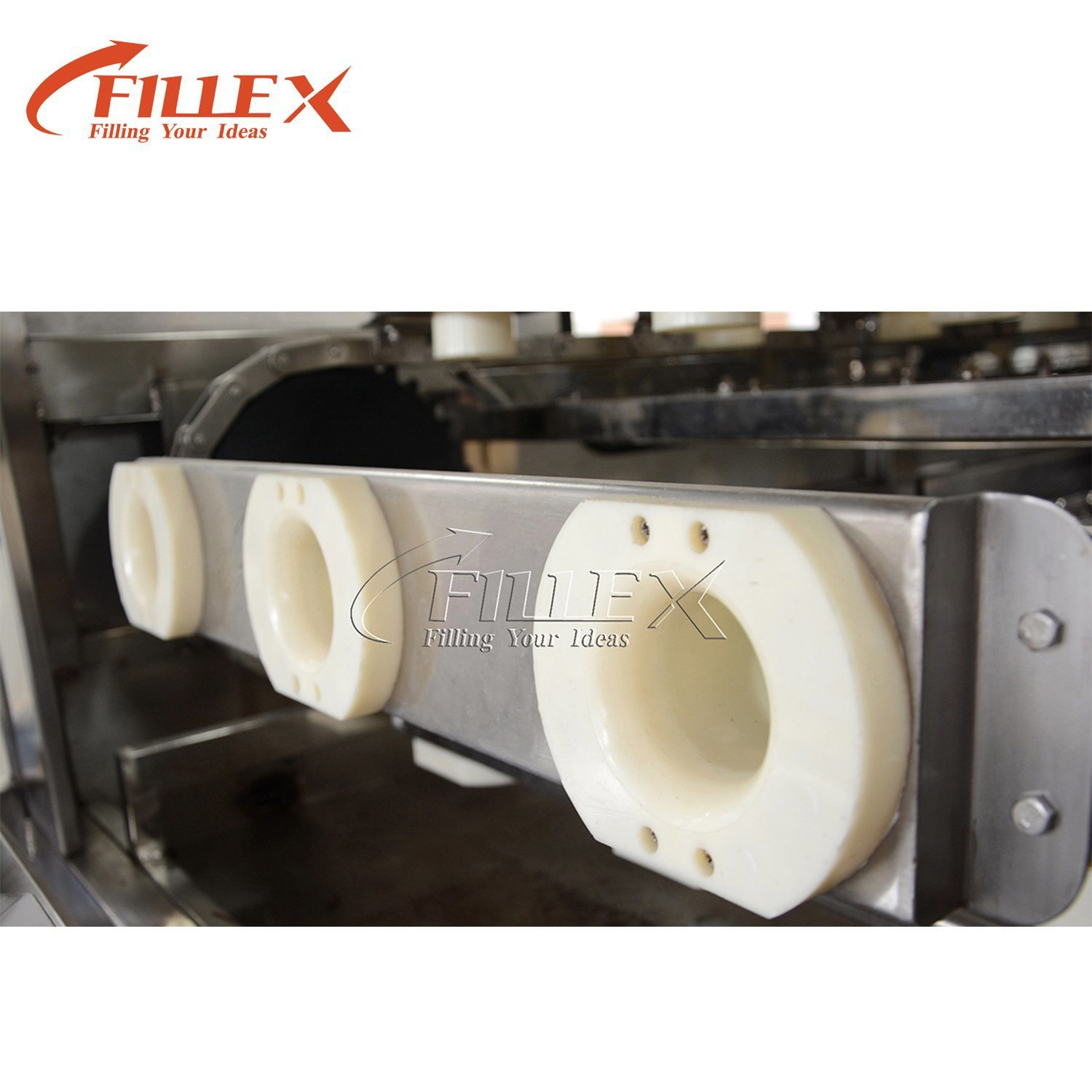

2. About washer

Nylon brushes, long life service life

Energy saving

The material of machine frame and body: all 304 Stainless Steel

No bottles no washing

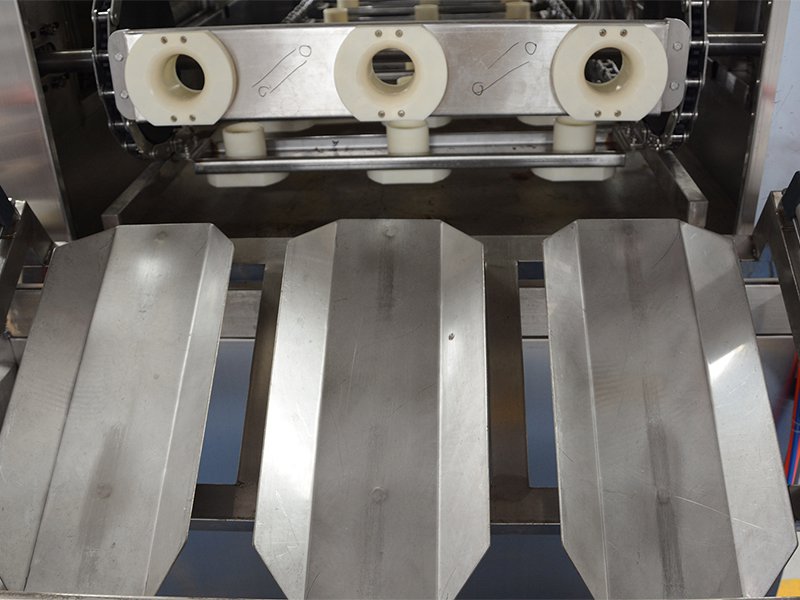

3. About the filler

Full-automatic PLC control, full-automatic working, filling level, filling time adjustable

Linear cylinder-pushed filling style, super high precision, ( when the capacity up to 800BPH, adopt the rotary filling system )

Food Class 304 or 316L stainless steel contact parts

No bottles no filling

1. This Barreled Water Production Line specially produce 3-5 gallons barreled drinking water.

2. It is controlled by PLC and made of SUS304 / SUS316.

3. It integrates bottle washer, filler and sealer into one unit.

4. In order to achieve the purpose of washing and sterilizing ,washing machine use multi-washing liquid spray and-thimerosal soray, this merosal can be used circularly.

5. The sealer can seal barrel caps automatically. This line equips with water spraying device in order to ensure those caps sterile and clean, also this line can automatically carry out barrel, washing, sterilizing, filling, capping, counting and products discharging.

Q1: Are you a trading company or a manufacturer?

A1: We have our own factory for many years, can give u best service.

Q2: What's your guarantee if we buy your machines?

A2: We offer you high-quality machines with a 1-year guarantee and free spare parts for 1 year. Meanwhile, our engineers have rich experience and have gone to more than 50 countries for installation and commissioning.

Q3: When can I get my machine after I paid?

A3: We will deliver the machines on time as the date we agreed on both sides.

Q4: How can I install my machine when it arrives?

A4: Our engineer will go to your side as soon as you get your machines ready for testing and teaching your technicians how to run the machines.

Q5: What's the delivery time?

A5: 30-45 days after the T/T deposit or L/C.

Q6: Do you provide customized service?

A6: We can design the machines according to your requirements (material, power, filling type, container and etc), at the same time we will give you professional suggestion by many years industrial experience.