- WhatsApp: / 008613773256419

- Email: Jessy@fillex-packer.com

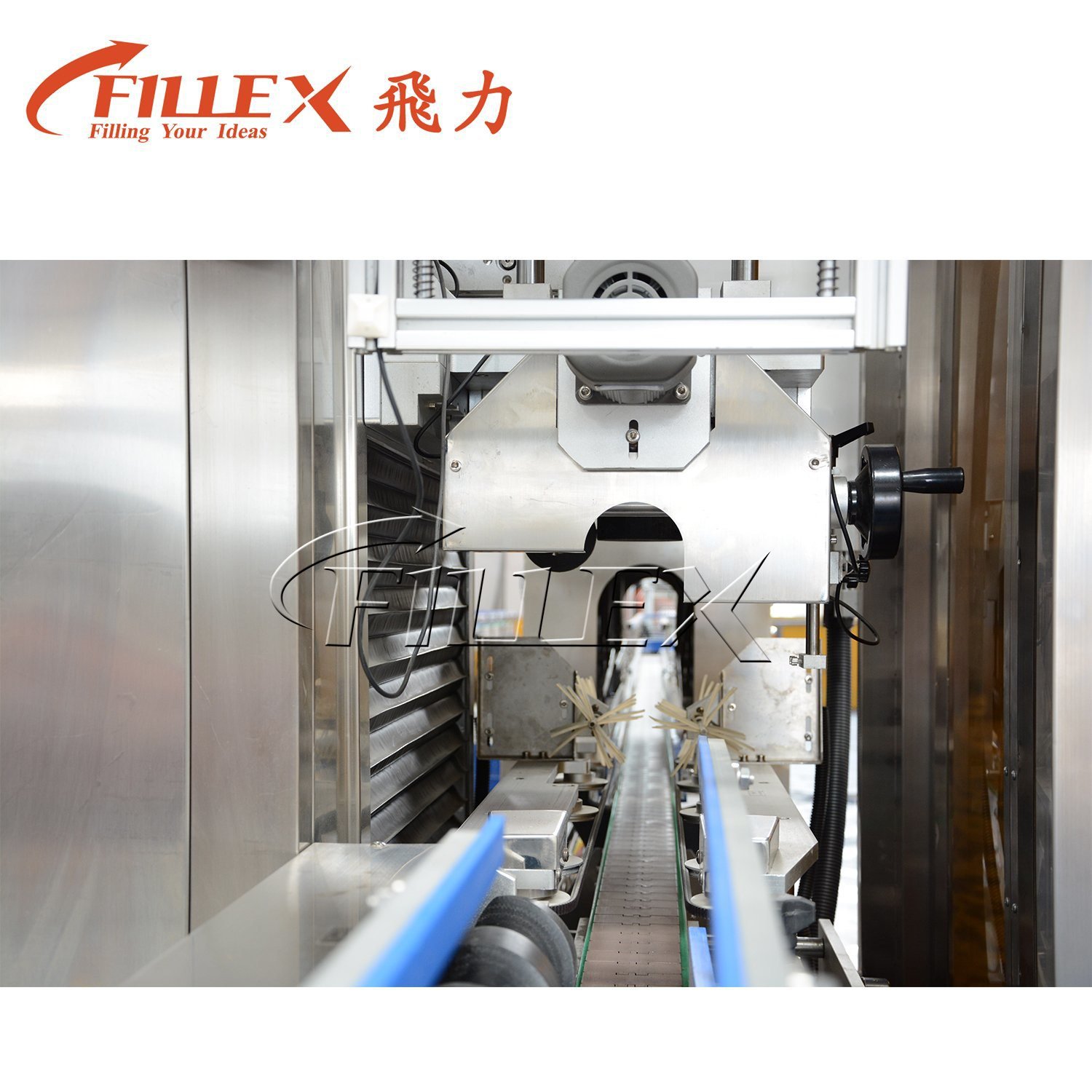

This auto shrink sleeve labeling machine is workable to apply PVC labels onto the water bottles or cans. It is widely used in the beverage and food industries.

This machine is used in 3L - 20L bottled water production line, it can improve the water factory production effective.

Label Steam Shrinking Tunnel:

1. Double layer holding furnace is manufactured to take effect on energy saving

2. The steam spray nozzle is divided to be adjustable three segments and the height, position and steam output of every segment can be adjusted respectively so as to gain the perfect shrinking effect.

3. The whole machine is made of 304 stainless steel with heat preservation

4. The stainless steel defrosting tray collects condense water.

5. The whole machine adopts the water-proof design with the convenience of operation and maintenance.

Model | Full Automatic 3L To 20L Bottle Cap Shrink Sleeve Machine |

Product Capacity | Standard speed is 50-80 bottles/min. |

Voltage specification | 1. Main machine: AC220V, 50/60Hz, single phase |

2. Shrinking oven: AC380V, 50/60Hz, 3 phases | |

Suitable label height | 60mm-120mm |

Suitable label length | 100mm-200mm |

Suitable label thickness | 0.03mm-0.13mm |

Suitable label material | PVC, PET |

Size of main machine | L800mm*W860mm*H1600mm |

Steam shrinking oven | Steam consumption: 50Kg/H |

Steam pressure: 1Kg/cm2 | |

Volume of oven: L2300mm*W400mm*H1500mm |

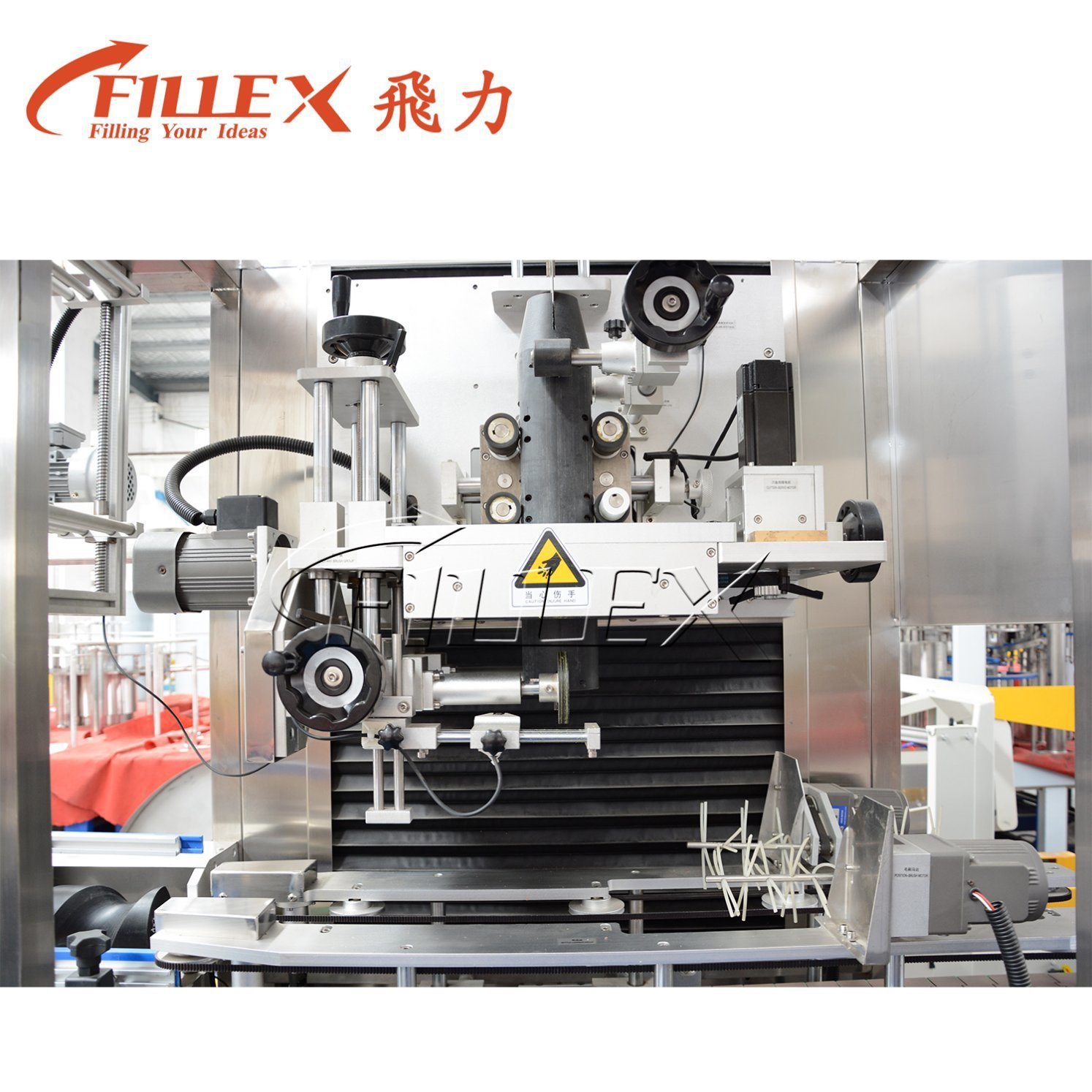

1. Shrinkage film volume label rack, match with adjustable device, convenient to adjust

according to differ volume label 5″~10″paper tube.

2. Simply installation, then can convenient for square and round bottle.

3. No need of instrument, rotary mechanism is convenient to adjust, apply to differ bottle type.

4. Unique sleeve labeling method, adopt to pressing sleeve labeling method,

not only convenient but also reasonable.

5. Auto controlling feeding system, level-off shrinkage film materials and regulate/adjust strain simultaneity.

6. Unique design knife plate, within specification scope, can avoid changing knife base,

knife changing is quick and conveniently.

7. Middle guide-pole clip system,mould changing is more quick, no need any instrument.

8. Label location system, can promote and demote in-phase adjust location according to specific bottle type requirement.

9. Adopt to Japanese import servo system and high-sensitivity photoelectric, label cutting precision is highly.

10. Stainless steel electric equipment controlling case, controlling adopt to Thinget PLC

11. Adopt to advanced man-computer Interface auto controlling technology, key electric component all adopt to international famous industrial brand

Q1: Are you a trading company or a manufacturer?

A1: We have our own factory for many years,can give u best service.

Q2: What's your guarantee if we buy your machines?

A2: We offer you high quality machines with 1 year guarantee and free spare parts for 1 year. Meanwhile our engineers have rich experience and have gone to more than 50 countries for installation and commissioning.

Q3: When can I get my machine after I paid?

A3: We will deliver the machines on time as the date we agreed both side.

Q4: How can I install my machine when it arrives?

A4: Our engineer will go to your side as soon as you get your machines ready for testing and teaching your technicians how to run the machines.

Q5: What's the delivery time?

A5: 30-45 days after the T/T deposit or L/C.

Q6: Do you provide customized service?

A6: We can design the machines according to your requirements (material, power, filling type, container and etc), at the same time we will give you professional suggestion by many years industrial experience.