- WhatsApp: / 008613773256419

- Email: Jessy@fillex-packer.com

Application Scope:

Adapted for various kinds of PET preforms,beverage bottle,cooking oil bottle,medical and cosmetic containers

Description | PET-2100-II | ||||||

International size rating | 880 | ||||||

Clamping Unit | |||||||

Clamping force | KN | 2100 | |||||

Opening stroke | mm | 490 | |||||

Space between tie-bars (HxV) | mm | 570 x 520 | |||||

Max. mold height | mm | 550 | |||||

Min. mold height | mm | 200 | |||||

Ejector stroke | mm | 150 | |||||

Ejector force | KN | 62 | |||||

E | H | ||||||

Injection Unit | A | B | C | A | B | C | |

Screw diameter | mm | 45 | 50 | 55 | 45 | 50 | 55 |

Screw L/D ratio | L/D | 22 | 20 | 18.5 | 22 | 20 | 18.5 |

Theoretical shot volume | cm3 | 367 | 491 | 594 | 367 | 491 | 594 |

Shot weight | g | 334 | 447 | 541 | 334 | 447 | 541 |

oz | 12.9 | 17.3 | 21 | 12.9 | 17.3 | 21 | |

Injection rate | g/s | 142.5 | 175.9 | 212.9 | 182.4 | 225.2 | 272.5 |

Injection pressure | Bar | 2235 | 1810 | 1496 | 2235 | 1810 | 1496 |

Plasticing capacity | g/s | 19.3 | 28.6 | 34.3 | 24.7 | 34.8 | 41.3 |

Screw speed | rpm | 0-176 | 0-226 | ||||

Others | |||||||

Max. pump pressure | Bar | 175 | 175 | ||||

Drive power | kw | 20.4 | 28.3 | ||||

Heating capacity | kw | 11.5 | 11.5 | ||||

Machine dimensions | m | 5.5x1.5x2.2 | 5.5x1.5x2.2 | ||||

Machine weight | t | 7.1 | 7.1 | ||||

Hopper capacity | Kg | 50 | 50 | ||||

Oil tank capacity | L | 300 | 300 | ||||

The shot weight is based on polystyene at specific gravity of 1.05

Due to continuous improvements, we reserve the right to amend any aspect of the above specifications without notice.

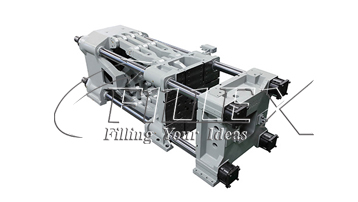

Larger space between tie-bars, suitable for larger molds and multi-cavity needs.

Longer and wider guide length, higher repeatability precision, improve product quality and mold lifespan.

Better designed mechanical structure and toggle system faster cycle time and improve production efficiency.

Full supported injection unit with dual precise linear guide rails, ensure the best precision and fast start speed.

Dual carriage cylinders improve the better injection precision.

Injection unit steel pipes adopt pipe fitting to connect, no welding design ensure maintenance and after-service to be easier.

Standard equipped with precise and energy saving servo motor system, energy saving capacity can reach to 20%~80% than traditional injection machine.

World famous brands hydraulic parts ensure the machine's reliability and fast response speed

Visible and dischargeable oil tank, easy for hydraulic circuit maintenance.

1.Superior shot weight, can meet the preforms large shot weight necessary.

2.Screw designed according to PET materials characteristics, breakthrough improvement on the defects of bubble, flow mark, white patch , yellowing, etc, products quality highly improved.

3.Increased plasticizing capacity, wonderful plasticization, preform color more uniform, production more stable.

4.Machine’s structure and spare parts optimized according to preform characteristics, product quality and efficiency is higher.

5.Increased ejection force fit for ejecting multi cavity preform.

6.Double-loop system can be for option, come true the simultaneous movement, production efficiency highly improved; At the same time, higher filling speed ensure products' internal stress reduced obviously, product quality higher.

7.Can option complete auxiliaries, such as: Dehumidified, Hopper dryer, Auto loader, Hot runner, Mold, Chiller etc.

8.Post-Mold Cooling (PMC) is available, production capacity can be highly improved (maximum 35% higher), lessened scratch from ejection, and risk-free from clamping against inefficient ejection.

Q1: Are you a trading company or a manufacturer?

A1: We have our own factory for many years,can give u best service.

Q2: What's your guarantee if we buy your machines?

A2: We offer you high quality machines with 1 year guarantee and free spare parts for 1 year. Meanwhile our engineers have rich experience and have gone to more than 50 countries for installation and commissioning.

Q3: When can I get my machine after I paid?

A3: We will deliver the machines on time as the date we agreed both side.

Q4: How can I install my machine when it arrives?

A4: Our engineer will go to your side as soon as you get your machines ready for testing and teaching your technicians how to run the machines.

Q5: What's the delivery time?

A5: 30-45 days after the T/T deposit or L/C.

Q6: Do you provide customized service?

A6: We can design the machines according to your requirements (material, power, filling type, container and etc), at the same time we will give you professional suggestion by many years industrial experience.