- WhatsApp: / 008613773256419

- Email: Jessy@fillex-packer.com

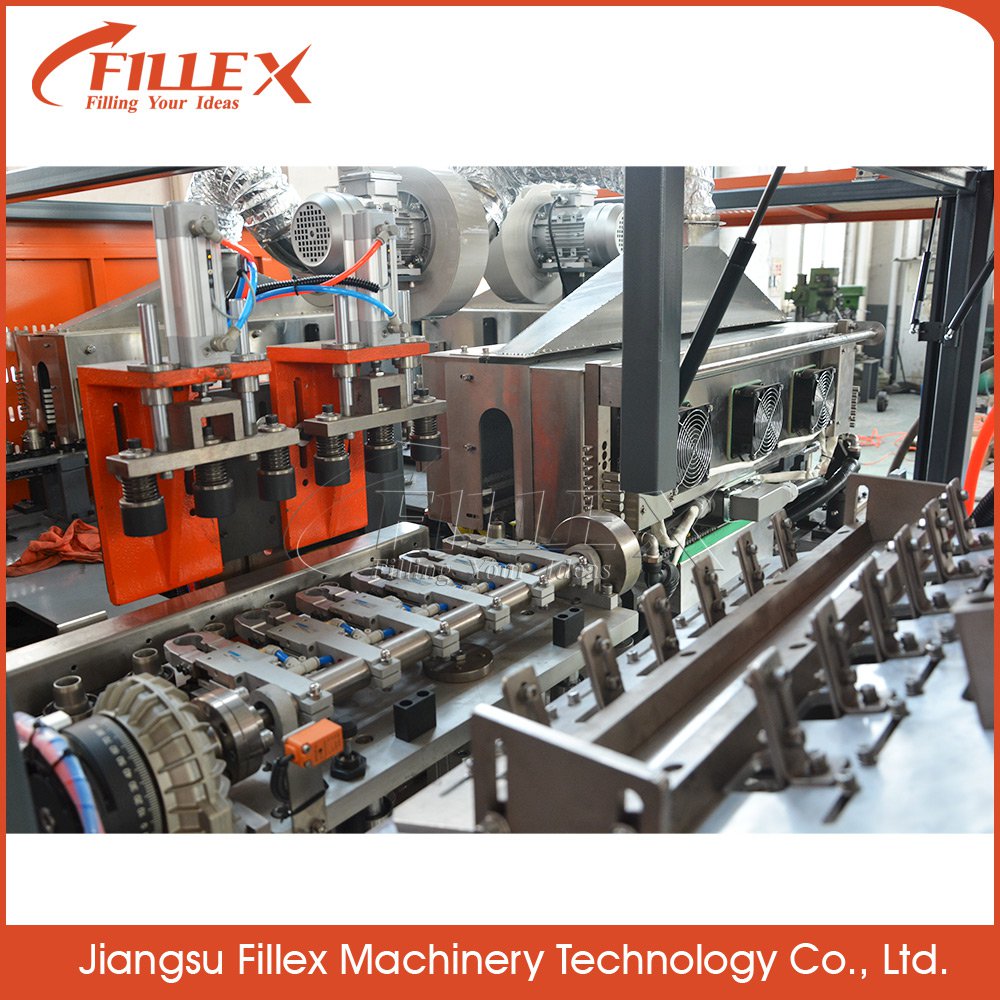

this series use for 10-20L big container

Clamping System | Number of Cavities | 2 Cavities | 1 Cavities |

Clamping Force | 65000 KG | 65000 KG | |

Mold Stroke | 260 mm | 320 mm | |

Stretching Stroke | 350 mm | 460 mm | |

Bottom Stroke | 50 mm | 50 mm | |

Cavity Pitch | 220 mm | 300 mm | |

Number of Holder | 80 PCS | 48 PCS | |

Container | Max.Container volume | 6000 ml | 25000 ml |

Max.Container Height | 350 mm | 460 mm | |

Max.Container Diameter | 180 mm | 230 mm | |

Max.Prefrom Height | 200 mm | 240 mm | |

Max.Neck Diameter | 45 mm | 65 mm | |

Theoretical Output | 1500 B/H | 400 B/H | |

Electrical System | Heating oven qty | 4*4 PCS | 4*4 PCS |

Number of lamp | 4*10 PCS | 4*12 PCS | |

Heating Power | 72 KW | 72 KW | |

Install Power | 82 KW | 80 KW | |

Voltage | 380V/50HZ | 380V/50HZ | |

Air System | operating pressure | 0.7-0.9 mpa | 0.7-0.9 mpa |

blowing pressure | 2.5-3.0 mpa | 2.5-3.0 mpa | |

high pressure air consumption | 4.8/30 L/min | 4.0/30 L/min | |

power | 60 KW | 44 KW | |

Chiller System | temperature | 9-13 | 9-13 |

pressure | 0.4 mpa | 0.4 mpa | |

power | 5 HP | 5 HP | |

Machine | Machine Dimension | 4.0*1.8*2.2m | 4.0*1.8*2.2 m |

Machine Weight | 4500 kg | 4500 kg | |

A. Stable performance with advanced PLC.

B. Conveying preforms automatically with conveyor.

C. Strong penetrability and good and swift distribution of the heat by letting the bottles rotate by itself and revolute in the rails simultaneously in the infrared preheater.

D. High adjustability to enable the preheater to preheat preforms in shapes by adjusting the light tube and the length of the reflecting board in the preheating area, and eternal temperature in the preheater with an automatic thermostatic apparatus.

E. High safeties with security automatic-locking apparatus in each mechanical action, which will make the procedures turn into a state of safety in case of a breakdown in certain procedure.

F.No contamination and low noise with the air cylinder to drive the action instead of the oil pump.

G. Satisfaction with different atmospheric pressure for blowing and mechanical action by dividing the blowing and action into three parts in the air pressure diagram of the machine.

H. Strong clamping force with high pressure and double crank links to lock the mold.

I. Two ways of operating: automatic and manual.

J. Safe, reliable, and unique design of the position of valve to make the air pressure diagram of the machine easier to understand.

K. Low cost, high efficiency, easy operation, easy maintenance, etc, with automatic technological process.

L. Contamination is avoided for the bottle body.

M. Ideal effect of the chilling with the chilling system.

N. Easy installation and starting

O. Low rejection rate: less than 0.3percent.

Q1: Are you a trading company or a manufacturer?

A1: We have our own factory for many years,can give u best service.

Q2: What's your guarantee if we buy your machines?

A2: We offer you high quality machines with 1 year guarantee and free spare parts for 1 year. Meanwhile our engineers have rich experience and have gone to more than 50 countries for installation and commissioning.

Q3: When can I get my machine after I paid?

A3: We will deliver the machines on time as the date we agreed both side.

Q4: How can I install my machine when it arrives?

A4: Our engineer will go to your side as soon as you get your machines ready for testing and teaching your technicians how to run the machines.

Q5: What's the delivery time?

A5: 30-45 days after the T/T deposit or L/C.

Q6: Do you provide customized service?

A6: We can design the machines according to your requirements (material, power, filling type, container and etc), at the same time we will give you professional suggestion by many years industrial experience.